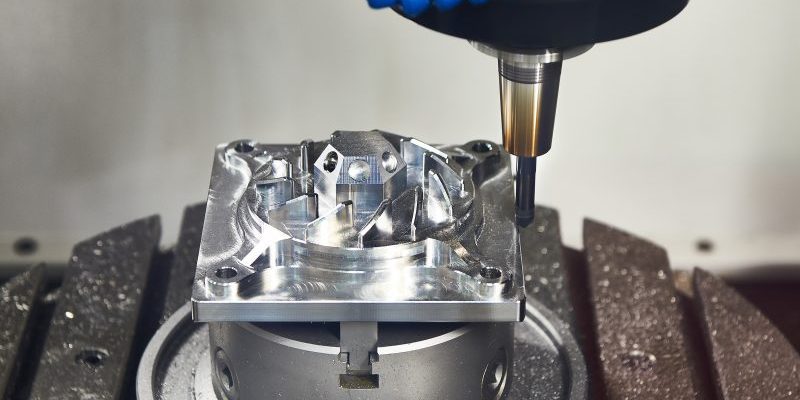

Javelin-Cimetrix through solution partners provide CNC Machining Services, including milling, and turning for the production of high-quality parts using modern machining methods. Our solution partner employs highly skilled machinists and industry-leading equipment to accommodate a vast array of manufacturing applications.

Learn more about the CNC services available:

CNC Machining Features

We can create complex and precise machined parts

Fast & Precise Part Production

Our partner has the capacity to create CNC machined parts with unrivaled speed.

At the same time, their experienced engineers ensure the highest standards with cutting edge software and equipment.

Our solution partner is dedicated to providing the fastest CNC machining in the industry, with projects programmed and started the same day as order.

Variety of Machines

Our partner operates more than 20 state-of-the-art machining centers with a wide variety of CNC equipment such as single axis lathes for executing round parts such as nozzles, engine components and thread shafts.

Plus 5-axis machines, which substantially reduce turnaround time by eliminating intermediate setups and enabling undercuts and off-axis features.

Part Finishing

We offer a variety of expertly applied finishing options to improve the mechanical and aesthetic properties of your CNC machine component, including painting, anodizing, EMI and RFI shielding and hand polishing.

CNC Machining can also be used to finish 3D printed parts that require boring, drilling, face milling or other precision machining for enhancing features.

CNC Machining Service Materials

Meet your most demanding and precise applications with CNC materials. Our partner can machine virtually any engineering material, including plastics, metals, alloys, and foam or tooling board.

Plastic Materials for CNC Machining

| Material | Description | Benefits | Applications |

|---|---|---|---|

| ABS | Low cost engineering plastic that is easy to machine and fabricate |

|

|

| Polycarbonate | Engineering plastic with excellent dimensional stability and good strength and stiffness over a wide range of service temperatures. |

|

|

| Polycarbonate 20% GF | 20% glass reinforced polycarbonate with higher temperature and tensile properties. |

|

|

| Nylon 6/6 | Type 6/6 is a general purpose, standard grade nylon. Extruded in natural and black. |

|

Ideal for metal replacement applications such as:

|

| 30% GF Nylon | 30% glass-fiber reinforced nylon 6/6 material with superior abrasion and wear resistance. |

|

- |

| Delrin | Crystalline plastic that offers an excellent balance of properties that bridge the gap between metals and plastics |

|

|

| HDPE | HDPE is used in a wide variety of applications and industries where excellent impact resistance, high tensile strength, low moisture absorption and chemical and corrosion resistance properties are required. |

|

|

| Polypropylene | Crystalline material noted for its high strength-to-weight ratio, excellent chemical resistance and high performance in thermoforming and corrosive environments |

|

|

| Clear Acrylic | Rigid, hard thermoplastic material that is characterized by its color range availability and easy fabrication |

|

|

| PVC | Normal impact, high corrosion resistant polyvinyl chloride |

|

|

| ULTEM™ 1000 Resin | Amorphous thermoplastic polyetherimide (PEI) material that combines exceptional mechanical, thermal and electrical properties; Natural ULTEM™ 1000 Resin (unreinforced) is a translucent amber material |

|

|

| ULTEM™ 1000 20% GF Resin | Addition of glass fiber reinforcement to the basic ULTEM™ Resin |

|

|

| G-10 FR4 | Versatile, all-around electrically insulating material |

|

Metal Materials for CNC Machining

| Material | Description | Benefits | Applications |

|---|---|---|---|

| Aluminum 6061 T6 | Generally selected where welding or brazing is required or for its high corrosion resistance in all tempers; Machining is more difficult when compared to the other machining alloys |

|

- |

| Aluminum 7075 T6 | Baseline 7XXX alloy with a good balance of properties required for aerospace applications |

|

|

| Mic 6 | Similar to those in the 7000 series with precise adaptable additions of Zinc, Copper, Magnesium and components of Silicon, Iron and Manganese |

|

|

| 303 Stainless Steel | Austenitic free-machining stainless steel used primarily for parts requiring machining, grinding or polishing |

|

|

| Mild Steel | - | - | - |

| Stainless Steel | - | - | - |

| Tool Steel | - | - | - |

CNC Machining Resources

Learn more about CNC Machining and Part Production

Interested in our CNC Machining Services?

Call us free at 1-800-298-6437 and get your questions answered