Aerospace Solutions

Satisfy customer requirements, maximize performance, and meet strict safety standards

Technology & Process Solutions

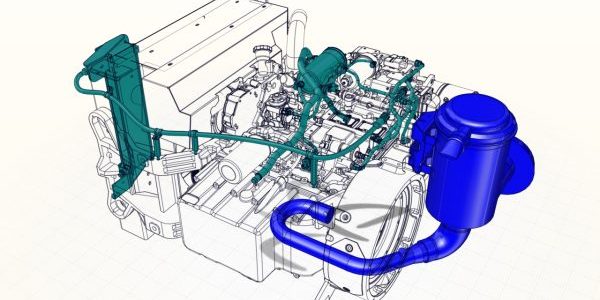

Javelin 3D Technology enables aerospace manufacturers to grow their businesses profitably while responding more rapidly to Requests for Quotes (RFQs) and Requests for Proposals (RFPs) with improved accuracy for pursuing new markets and taking on new competitors.

Our solutions allow aerospace designers to:

-

Work with a single centralized Bill of Materials (BOM)

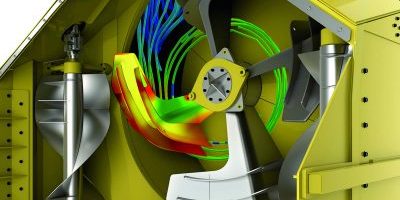

Define, communicate, collaborate, and predict how designs will perform so they can be optimized before they are built.

-

Design and Analyze Parts

Design complex machined and sheet metal parts, work concurrently in 3D and create flat patterns.

-

Reuse Existing Parts

Minimize redundant parts and change modifications by finding and leveraging existing parts.

-

Manage Product Development

Technology that facilitates multi-site manufacturing, supply chain operations and quality compliance.

Additive Manufacturing Solutions

3D printing provides manufacturers with prototyping, advanced tooling and production applications. 3D printed parts are now commonplace on aircraft and spacecraft — cementing the technology as an engineering mainstay.

Our additive solutions allow aerospace manufacturers to:

-

Create certified production parts

Fly with less weight, reduce complexity, and simplify production with certified 3D printed parts.

-

Conduct Rapid Prototyping and 3D print Injection Molds

Solve design challenges before committing to expensive and time-consuming tooling and production.

-

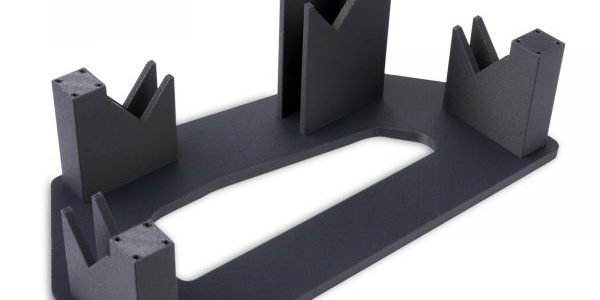

3D Print Composite Tooling

Streamline the cost and complexities of aerospace production with on-demand composite tools.

-

3D Print Jigs and Fixtures

With 3D printed tooling you can avoid high machining costs for custom tools or parts needed for individual repairs and restorations.

Customer Example

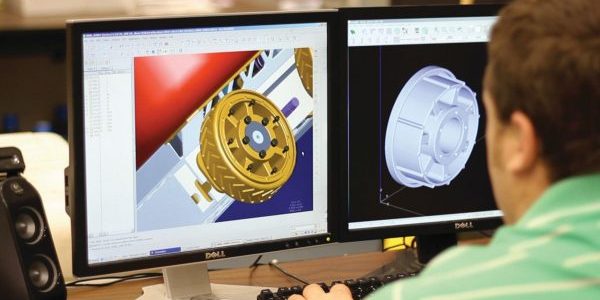

How Aerospace Engineers use SOLIDWORKS Technology

Based in Waterloo, Ontario, Aeryon Labs design Small Unmanned Aerial Systems (sUAS) for a range of applications around the world.

Aeryon use SOLIDWORKS solutions to create molds, test their drones, and optimize the aircraft’s weight and performance, passing savings and benefits on to their customers.

Additive Manufacturing Aerospace Solutions

Advanced materials and techniques for part production

Overview

Production expertise is critical to many of our aerospace customers. Javelin has an expert aerospace manufacturing engineering team with critical technical knowledge.

Our industry knowledge and our abilities to support high requirement applications is what brings aerospace companies to us. Direct Digital Manufacturing (DDM) with additive manufacturing allows for the creation of rigid, lightweight aerospace parts, leveraging advanced materials such as Ultem 9085, not achievable with other manufacturing methods.

Our customers, such as L3, Bombardier, Boeing and Standard Aero are but a few partners benefiting from these advancements in additive technologies and materials. Like others in the aerospace industry, they are experiencing performance improvements with superior lightweight part design from integrated structures and component consolidation.

By reducing weight, part count, design constraints and supply-chain risk, additive manufacturing is creating new production efficiencies for the aerospace industry.

Typical Applications

Our software and additive solutions help aerospace designers and manufacturers to produce:

- Enclosures & Interior Panels/Components

- Liquid and Fuel Tanks

- Gimbals

- Grommets & Clips

- Air Flow Ducts

- Control Surfaces

- UAV Components

- Mounting Brackets

Additive Manufacturing Applications

How do Aerospace engineers use 3D printers?

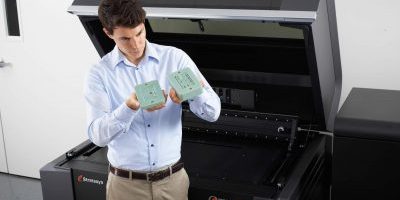

Production End-use Parts

Stratasys 3D Printers are ideal for low production runs as they build the most durable, stable, repeatable on-demand end-use parts in the industry

Rapid Prototyping

Rapid prototyping with a Stratasys 3D Printer helps companies turn great ideas into successful products faster than ever before by 3D printing your prototypes.

Why Stratasys 3D Printing for Aerospace?

Create Components Faster

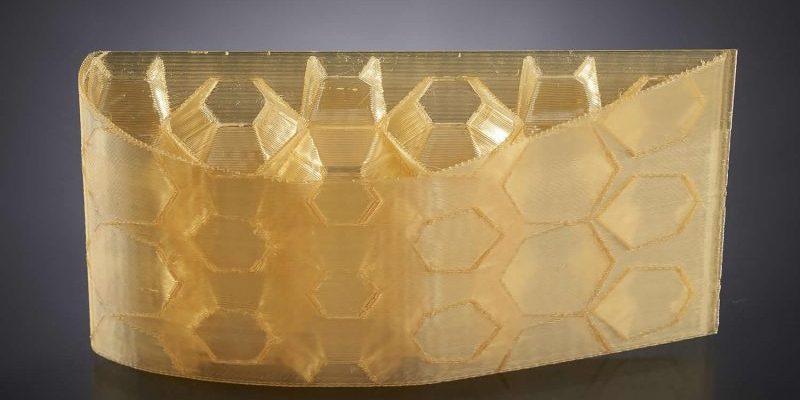

Stratasys FDM machines work with production grade thermoplastics including ULTEM 9085, which provides an ideal solution for the manufacturing of component parts for aircraft, as it is lightweight and able to withstand intense heat (flame retardant).

Reduce Production Costs

By replacing expensive and lead-time critical CNC-milled parts with in-house manufactured plastic parts, you can dramatically reduce your production costs. The printed plastic parts also perform better technically, weigh less, and provide better electrical insulation.

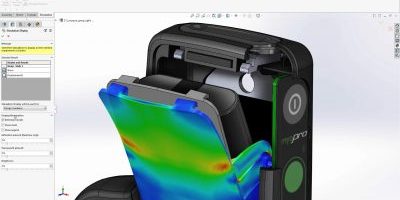

Improve performance with Composite Parts

Improve production efficiency and flight performance while simplifying inventory with strong, lightweight composite parts. Also save time and find more ways to optimize by 3D printing your tooling for composite parts. For interior components, soften the impact of late design changes to keep production on track. 3D print flight-ready parts like housings and duct work in-house with certified, traceable material.

Featured Solution

Produce Certified Aircraft Interiors with 3D printing

Certifying additively manufactured parts for aircraft installation just got a lot easier.

The Stratasys Certified Aircraft Interiors gives aerospace companies a faster, more streamlined process.

Interested in an Aerospace solution?

Call us free at 1-877-219-6757 and get your questions answered